Description

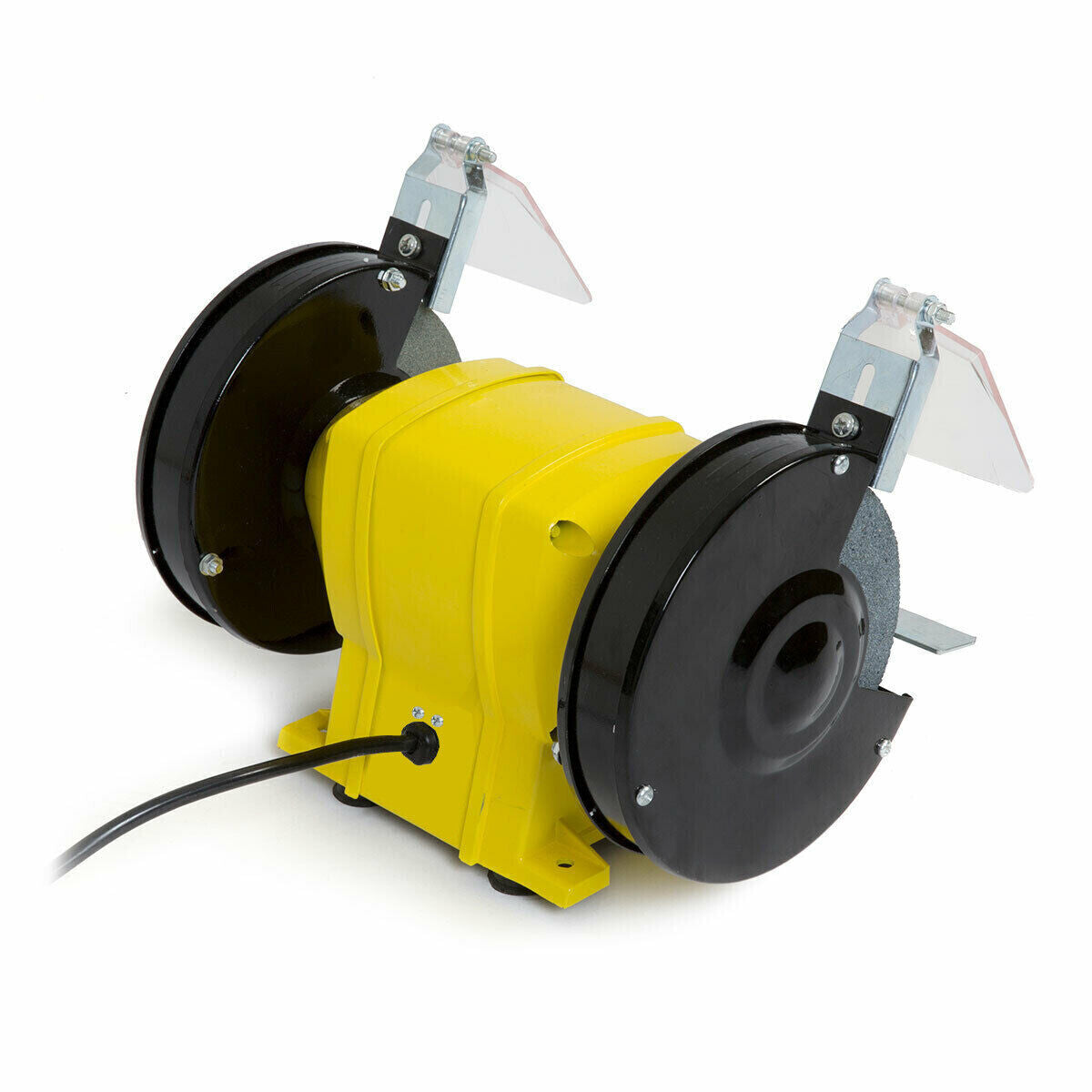

A cast alloy body of flat front design houses a 240v 250w induction motor,

providing sufficient power for the work this type of machine is put to.

The centre motor spindle protrudes from both sides of the central housing and is supported on ball bearings in the side casing journals;

the spindle ends are threaded to fix the 6"grinding wheels with dished clamping washers and nuts.

The front face has a specification plate above the on/off switch.

Steel safety guards are mounted around both wheels and each consists of inner plate which stays in place but the outer is removable to facilitate stone replacement or service.

Whilst the stones are balanced to themselves in manufacture grinding wheels have to be "Trued by dressing" on the grinder.

The grinding wheels have lead centres to allow for 'truing' with a dressing wheel or a scrap piece of bar steel to ensure that the initial wheel wobble is removed (this the equivalent of wheel balancing).

See through eye shields are fitted to the front top of the guards to protect the eyes although we do recommend that a pair of CE approved safety specs should also be worn when using any grinding tool.

The tool rests bolted to the inner guards and are adjustable to suit.

Anti-vibration mountings and bench fixing holes are provided enabling the grinder to be bolted to a bench or stand.

The grinder comes fitted with two grinding wheels, each 150mm diameter, 20mm wide and 12.7mm bore 12.7mm. The coarse one is manufactured from 36 grit & the medium 60 from grit.

Technical Specification:

- Motor: 250W Induction Motor

- No Load Speed: 2950rpm

- Grinding Stones:

- 150x20mm (1x Coarse - 36 grit, 1x Medium grit - 60 grit)

- Spindle bore:12.7mm

- 2x Protective Eye Shields

- 2x Tool Rests